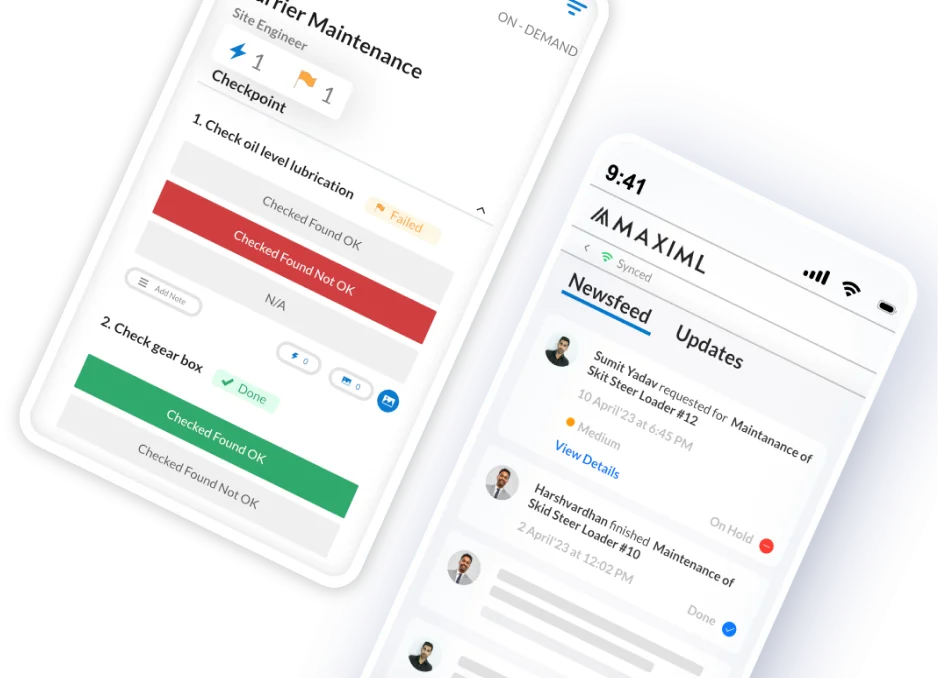

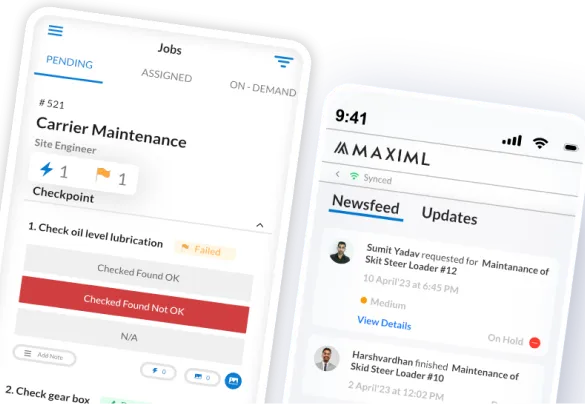

From the shop floor to the field, our no code platform enables digital implementation at scale.

Digitalization is set to unlock $1.6 trillion through operational excellence in the Oil and Gas industry. Our digital solutions enable faster turnaround execution, reduce down-time by digitizing maintenance and diagnostics, and connect your workforce to track workers and job progress on sites.

The power sector can unlock $1.3 trillion of value through digitalization. Our solutions improve operational efficiency by using digital workflows, standardizing maintenance activities with visual SOPs, and avoiding job delays by staying connected with the field.

Digitalization could unlock $550 billion in the chemical industry by automating 47% of manual tasks. Our solutions enable continuous remote monitoring to increase asset reliability, task assignment to field technicians based on location and priority, and provide digital insights across operations, locations, and teams.

Digitalization can cut CO2 emissions by 610 million tonnes and generate over $425 billion in the next decade. Our solutions streamline operations to optimize material and equipment flow, monitor compressors, pumps, and motors to reduce downtime and delays, and improve resource optimization and anticipation of failures with real-time data.

Maximl’s Connected Worker Platform accelerates time-to-market with secure and compliant access to critical knowledge, valuable for pharmaceutical companies seeking to optimize operational efficiency and streamline compliance while ensuring effective job performance.

Maximl helped BPCL to optimize their Asset Monitoring

“Maximl Asset Monitoring tool is an effective solution, gives us continuous feedback and visibility of the status of the activity”

Head of Turnaround

BPCL

Maximl helped Indian Oil to streamline their shutdown activities

“Maximl STO tool assisted us in regular monitoring of shutdown activities, delay aversion of critical tasks and structured daily reviews with management”

CGM,

IOCL, Paradip

Maximl helped Bharat Petroleum to monitor their shutdown activities in real-time

“Maximl STO helped us in active monitoring of the progress of the shutdown activities and enabled us to complete the shutdown on-time”

CGM-Ops,

BPCL, Kochi

Maximl facilitates cross-departmental communication growth at Bharat Petroleum

“Maximl filled the most important gap that has existed i.e., the gap in inter-personal or inter-department/section communication. This time all information was available to me at all times through your interactive & user-friendly solution”

Maintenance Planning Head

BPCL

Maximl helped Hindustan petroleum to take real-time critical decisions on field

“Maximl’s Project Management solution unifies data from multiple users on to a shared platform in near real-time. This helps us take quick decisions during schedule sensitive projects like Refinery Turnaround.”

Maintenance Planning Head

HPCL

Maximl helped Reliance Industries Limited to optimize their STO processes

“Maximl’s solution helped us greatly in efficient collaboration on shutdown activities, dynamic CP analysis and automated dashboards for reporting.”

Group Lead, CoE

Reliance Industries Limited

Maximl helped NRL to improve their inspection processes

“It’s a game-changer for us! The implementation of Maximl’s solution for turnaround proved to be effective in improving our inspection processes when it comes to improving asset reliability and quality of inspections.”

DGM Inspection

NRL

See how Singapore’s refining major streamlines valve maintenance to improve on-field productivity

Eastern India’s largest refinery achieves major success with 30% reduction in on-field issues

Find out how this company is setting the standard for employee safety in Brazil’s real estate market

Breaking new ground: How this European giant is creating a safer workplace through digital innovation

Paving the way for safety: How this Peruvian company is leveraging digital technology to enhance workplace safety

Find the right solution for you

Learn more about Connected Worker Platform

Collaborate & augment the workforce