Improve the quality, transparency, and efficiency of maintenance and repair procedures.

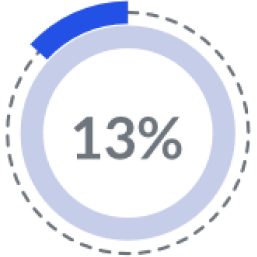

Only 13% of manufacturers have real-time visibility of their manufacturing processes

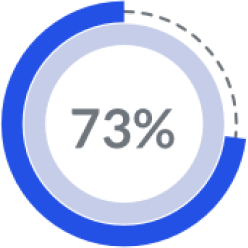

73% of variability on the factory floor stems from humans

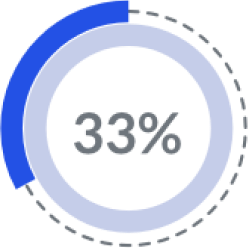

Nearly 33% of frontline employees do not receive any formal workplace training

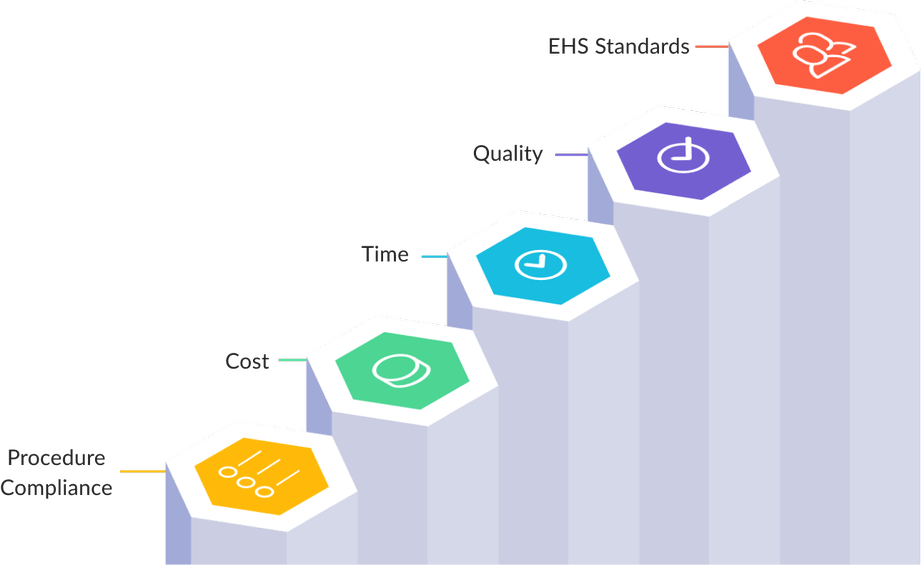

Improve safety compliance

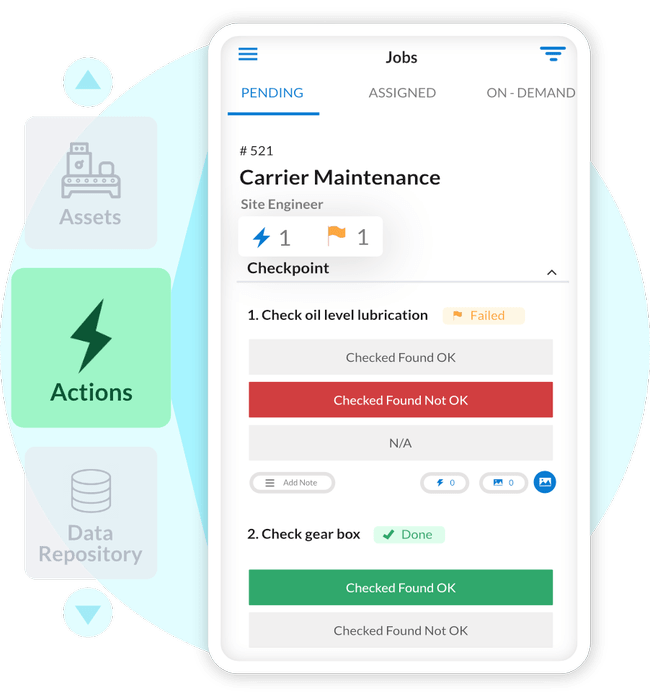

Capture human activity data

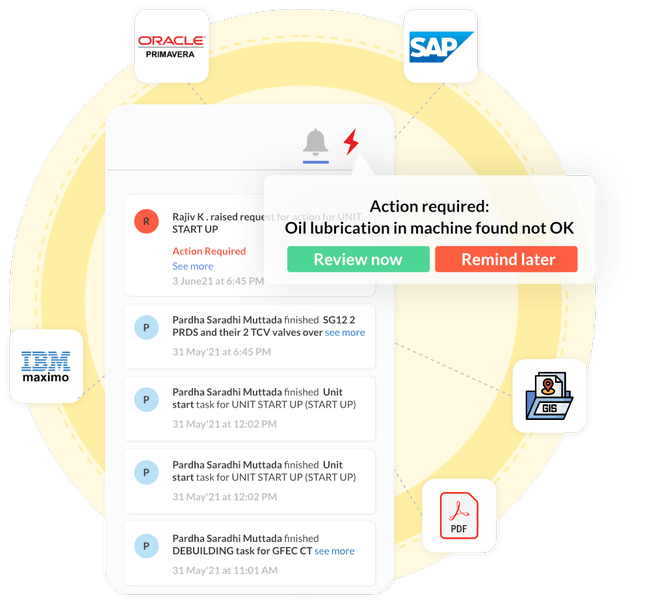

Increase team collaboration

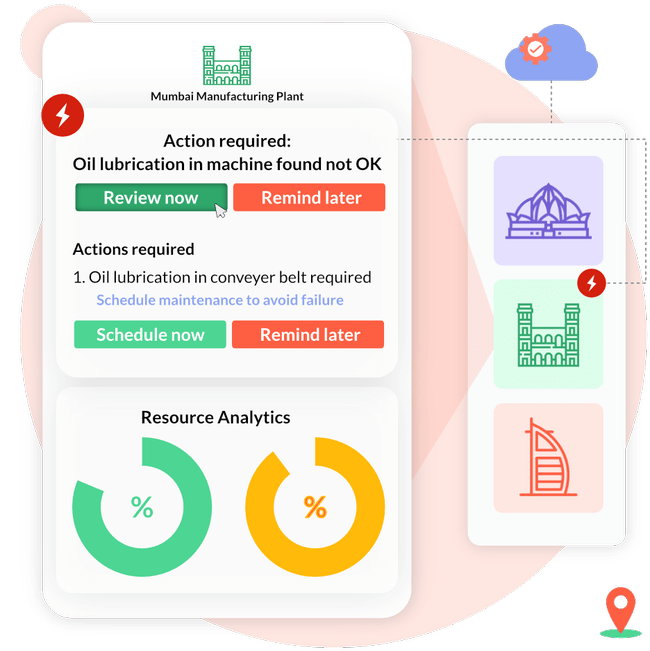

Achieve operational efficiencies

Prevent unexpected shutdowns & Accidents

Improve MTBF and MTTR

Reduce Maintenance Cost

Enhance visibility and streamline asset management

Maintenance operations are complex and often performed based on tribal knowledge and with the help of static non-interactive SOPs

36% of total unplanned downtime can be prevented by standardized maintenance practices

8% of revenue is lost due in unplanned downtime by fortune 500 global players in process industry

30% of safety incidences are during unplanned maintenance activity

Create interactive SOPs to guide your maintenance teams. Bridge knowledge gaps with remote learning and access to digitized tribal knowledge. Track asset performance at all times with remote monitoring.

Monitor process completions remotely to detect and solve bottlenecks faster. Make faster decisions with real-time progress reports. Maximl integrates with your ERP, CMMS, and GIS systems to unify data and give comprehensive insights.

Remote asset information helps cut down costs of manual inspections. Automatically plan and schedule maintenance projects, and optimize resource allocation. In case of emergencies, have immediate data on whereabouts.

Reduction in non productive time (NPT)

Increase in OEE

Reduction in new hire training time

Reduction in Mean Time to repair (MTTR)

Reduction in Mean Time to repair (MTTR)

Decrease in re-work

Decrease in start-up/ changeover time

Maximl helped BPCL to optimize their Asset Monitoring

“Maximl Asset Monitoring tool is an effective solution, gives us continuous feedback and visibility of the status of the activity”

Head of Turnaround

BPCL

Maximl helped Indian Oil to streamline their shutdown activities

“Maximl STO tool assisted us in regular monitoring of shutdown activities, delay aversion of critical tasks and structured daily reviews with management”

CGM,

IOCL, Paradip

Maximl helped Bharat Petroleum to monitor their shutdown activities in real-time

“Maximl STO helped us in active monitoring of the progress of the shutdown activities and enabled us to complete the shutdown on-time”

CGM-Ops,

BPCL, Kochi

Maximl facilitates cross-departmental communication growth at Bharat Petroleum

“Maximl filled the most important gap that has existed i.e., the gap in inter-personal or inter-department/section communication. This time all information was available to me at all times through your interactive & user-friendly solution”

Maintenance Planning Head

BPCL

Maximl helped Hindustan petroleum to take real-time critical decisions on field

“Maximl’s Project Management solution unifies data from multiple users on to a shared platform in near real-time. This helps us take quick decisions during schedule sensitive projects like Refinery Turnaround.”

Maintenance Planning Head

HPCL

Maximl helped Reliance Industries Limited to optimize their STO processes

“Maximl’s solution helped us greatly in efficient collaboration on shutdown activities, dynamic CP analysis and automated dashboards for reporting.”

Group Lead, CoE

Reliance Industries Limited

Maximl helped NRL to improve their inspection processes

“It’s a game-changer for us! The implementation of Maximl’s solution for turnaround proved to be effective in improving our inspection processes when it comes to improving asset reliability and quality of inspections.”

DGM Inspection

NRL

Find the right solution for you

Learn more about Connected Worker Platform

Collaborate & augment the workforce