Trusted by giants across verticals, Maximl is the leading solution provider for digital STOs.

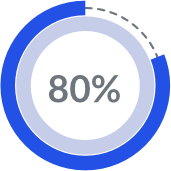

80% of all turnarounds do not meet established goals.

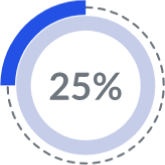

Approximately 1 in 4 turnarounds are considered to be total “train wreck” failures

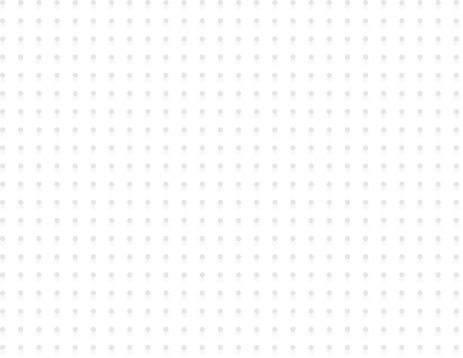

STO presents a unique management challenge where complex industrial assets are overhauled in a stringent HSE environment involving intricate tasks with multiple equipment, tools and units, to be performed by interdependent teams across large sites.

Completing the pre-defined scope of TA maintenance on time and within allocated budget, while maintaining high quality and EHS standards

of maintenance budget is consumed by Turnarounds

40% of turnarounds suffer delays due to scope creep

30% cost saving opportunity in turnaround management

Configure permissions and increase visibility of scope to minimize scope creep

Initiate worklist requests with a single click

3X faster prioritization of maintenance activities through integrated budget and criticality metrics

2X Faster decision making with real-time dashboards

Fully integrated with CMMS and ERP

Scope requisition and approval on single

platform for all departments

Centralised tracking of resources/materials/service contracts

Measure preparedness index for superior decision making

Integrated data management i.e., reference documents, schematics, IWL

Easy integration with ERP for procurement status

Drag and drop from industry standard data base (sequence, duration) for faster planning

Create your own industry data base for every asset; enabling benchmarking/standardization

Real time collaboration between peers for better review mechanism

Import finalized scope into your schedule in a click (WBS)

Create once, share across sites and run them anywhere, anytime.

Easy integration of post data on ERP

Real time update of job from the shopfloor

Integrated system to track defects status with evidence proofing and audit trails (Before and After of asset)

Get real-time update of jobs with rich media from the shopfloor

Real time dashboards and automated reports for faster & data-driven decision making

Live schedule monitoring and QA/QC compliance of every asset

Digital repository of actuals and history of actions taken by users of every task

Centralized knowledge management with curated asset data of every turnaround and benchmark across sites

Rich media captured in turnaround

Digital repository of asset QA/QC compliance with audit trails (before and after)

Benchmarking of asset data across timeline and sites

Decrease in total turnaround duration

Elimination in unplanned operational delay

Faster action resolution

Reduction in execution time for equipment box up

Reduction in execution time for equipment box up

Reduction in total turnaround cost

Maximl helped BPCL to optimize their Asset Monitoring

“Maximl Asset Monitoring tool is an effective solution, gives us continuous feedback and visibility of the status of the activity”

Head of Turnaround

BPCL

Maximl helped Indian Oil to streamline their shutdown activities

“Maximl STO tool assisted us in regular monitoring of shutdown activities, delay aversion of critical tasks and structured daily reviews with management”

CGM,

IOCL, Paradip

Maximl helped Bharat Petroleum to monitor their shutdown activities in real-time

“Maximl STO helped us in active monitoring of the progress of the shutdown activities and enabled us to complete the shutdown on-time”

CGM-Ops,

BPCL, Kochi

Maximl facilitates cross-departmental communication growth at Bharat Petroleum

“Maximl filled the most important gap that has existed i.e., the gap in inter-personal or inter-department/section communication. This time all information was available to me at all times through your interactive & user-friendly solution”

Maintenance Planning Head

BPCL

Maximl helped Hindustan petroleum to take real-time critical decisions on field

“Maximl’s Project Management solution unifies data from multiple users on to a shared platform in near real-time. This helps us take quick decisions during schedule sensitive projects like Refinery Turnaround.”

Maintenance Planning Head

HPCL

Maximl helped Reliance Industries Limited to optimize their STO processes

“Maximl’s solution helped us greatly in efficient collaboration on shutdown activities, dynamic CP analysis and automated dashboards for reporting.”

Group Lead, CoE

Reliance Industries Limited

Maximl helped NRL to improve their inspection processes

“It’s a game-changer for us! The implementation of Maximl’s solution for turnaround proved to be effective in improving our inspection processes when it comes to improving asset reliability and quality of inspections.”

DGM Inspection

NRL

Find the right solution for you

Learn more about Connected Worker Platform

Collaborate & augment the workforce