What Maximl does

Maximl, founded in 2016, offers AI-powered industrial automation software that helps major oil refineries, optimize maintenance operations, reduce downtime, and be safer and more compliant with regulations and industry norms. Maximl’s software is live at some of the largest oil refineries in the world, including the largest (Reliance, Jamnagar).

In addition, we serve various process sectors: petrochemicals (such as Haldia Petrochemicals), metals (Hindustan Zinc), power generation (Vedanta Power), and upstream oil (Vedanta Cairn). These are some of the largest companies in their sector – globally.

We offer software in two areas – Shutdowns, Turnarounds, and Outages (STO) and Control-of-Work.

The philosophy of software design guiding Maximl’s products

Maximl has several levers to achieve the ask of a 10X improvement:

An UX purpose built for the target group – the deskless industrial worker

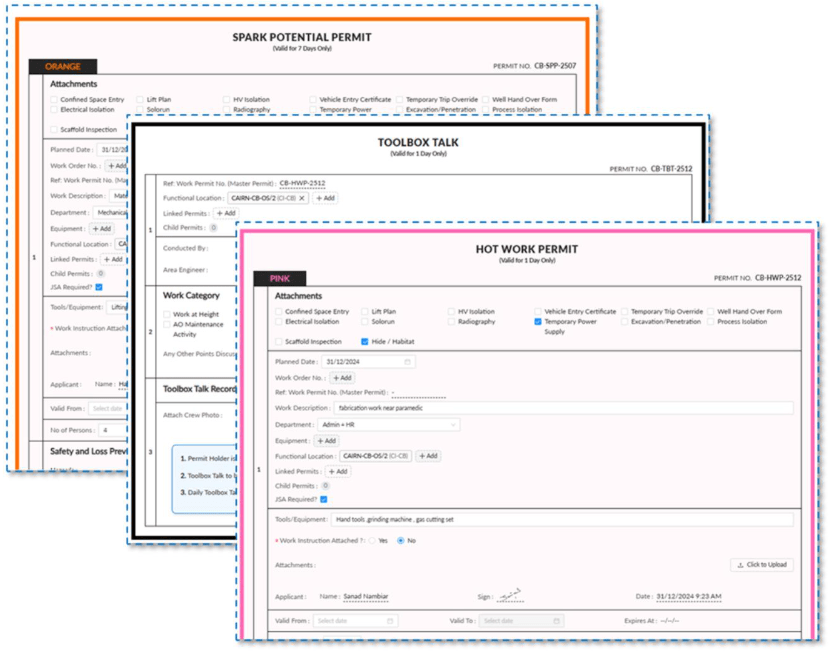

For the industrial workers doing or supervising the maintenance work on site, the UX is mobile, resembles paper-printed forms with coloured labels, and works well in the offline mode (syncing when the connection

comes back up).

Uses AI/ automation /Low code/ no code to ease data entry and processes safer and efficient – enabling work done right, not populating MIS with data

Industrial field workers cannot be asked to set aside time for record keeping to feed the enterprise software ecosystem. They already have much to do.

Therefore, any system of record for the deskless industrial worker must make the work better – to the point that it’s in the interest of the worker to use the software, even in the absence of any top-down corporate mandate.

Otherwise, it’s a non-starter. This isn’t B2B software sales where the salesperson can be asked to enter all opportunities in the CRM.

This is achieved in three ways.

- Classic AI – to extract tabular, useful information from documents. First, through a combination of computer vision (CV) and natural language processing (NLP) algorithms extracting usable tabular data from technical diagrams, integration with ERP, and data captured from actual site processes (such as inspection reports), we build a dynamic representation of actual plant operations that elevates maintenance operations to a level of safety and efficiency unachievable through the status quo – paper, group chat, and gut feel.

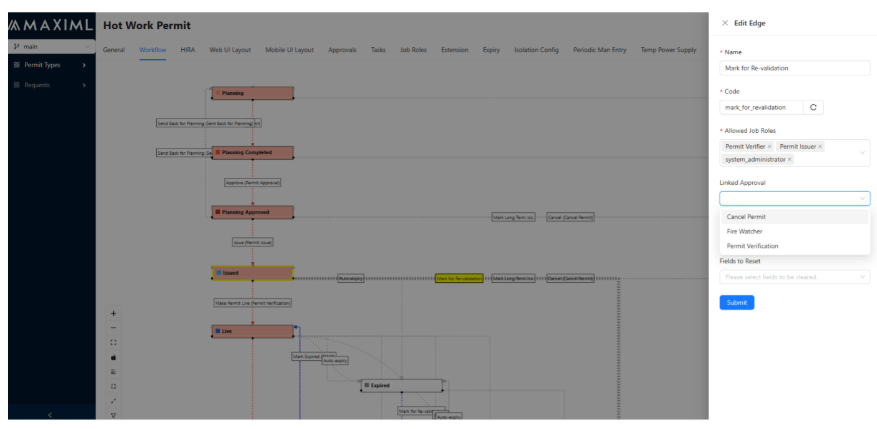

- Low code/no code configurability for plant management: The PTW issuance workflows, tasks lists, the rules governing maintenance orders, and the permit document’s UX can all be customised with little help from IT. The appearance of every element of the permit from the structure of forms to colour codes can be configured with a low code tool.

- AI, Gen AI, and standard automation to do the bulk of data entry. Third, we auto fill forms and automate data entry wherever possible using past work and artefacts as permits that have been used. We save a ton of time wherever practicable to the point where the alternative (paper) seems too cumbersome.

- In effect, our platform builds a knowledge graph of assets, jobs, and processes – the equivalent of the data model in standard B2B software such as CRM. Getting industrial maintenance right is about mapping asset to asset (which valve is attached to which pipeline), asset to job (which heat exchanger will be cleaned with jet pressure water), job to job (which two ‘hot work’’ jobs are happening at the same time?), and a job to process (which permit allows a particular job). This is an analogue of the data model that powers standard enterprise software such as ERP and CRM. A plant doesn’t have the luxury of setting aside time to build a data model because the data simply doesn’t exist in a structured form. Therefore, we make do with data that actually exists and aim for a knowledge graph-level structure, harvested from unstructured repositories with AI tools.

The conditions that shaped how we do what we do – both in STO and PTO

Maximl was incorporated in 2016 and got its first break in the world’s largest refinery. Our clientele includes 22 out of the 23 oil refineries in India. Over time, expertise built in downstream oil transferred to other process industries. We count metal, power generators, and petrochemical majors as clients. Our PTW solution is live at India’s largest private upstream company as well (Vedanta Cairn)

Maximl’s path, shaped both by intent and circumstance, has made us particularly suitable for a manufacturing niche defined by a specific set of characteristics.

- Extreme potential hazard. All manufacturing entails potential harm to life and limb. But large process engineering facilities, such as oil and petrochemicals, if not managed right, can leak chemicals and energy into the broader community, causing industrial disasters – the effects of which last decades and generations. Our software came out of this environment.

- Our user group is a mix of planners and on-site workers – both groups away from the corporate HQ. Planning large-scale maintenance activity (or routine maintenance) and the execution of tasks are different lines of work and require different interfaces and features. Our software and skill set as a maker of technology evolved to meet the needs of these two groups. For planners, we have focused on deriving data and intelligence out of past plans, libraries of job packages, inspection reports and technical diagrams. For those executing, we have focused on getting the mobile UX right.

- Our target user group hates software. Oftentimes this is for good reason. They have much to do. A mechanical or electrical engineer has the highly complex task of ensuring all maintenance projects are planned and executed in accordance with the highest norms of quality (and of course – ensuring production runs along expected lines). They shouldn’t also have to master software. Our platform has evolved over the years to look and feel like paper on screen – with the interactivity of software,

- RoI is easy to measure in our niche, particularly STO. Our roots are in helping the refinery manage turnaround better. Each day shaved off the time the plant stays unproductive represents over a million dollars in direct savings. Everything about our software therefore is geared towards generating real, tangible, and measurable benefits. This heritage finds reflection in our PTW offering as well. In the crowded PTW software landscape, most solutions are aimed at EHS compliance. Maximl does that too, but also makes the maintenance process more efficient.

- Our buyers are pragmatic, domain-focused asset management leaders. The buyer demographic knows requirements inside out, is focused on value, and has little use of technology trends. Operating in this niche, we too have learned to be cautiously optimistic to hype (and miscellaneous fashionable distractions), and stay aligned with the trifecta of cost, performance, and safety. To illustrate, we do use gen AI, but opportunistically. To aid decisions on the field. We have no interest in going full agentic AI.

In summary, we are solving one immediate problem, which is to reduce turnaround downtime. The bigger story is that we are using AI to make asset maintenance faster and safer. And in the broadest terms, the most intractable problem we are solving is building software for the deskless industrial employee – software that forms the seat of operational work.