What Maximl does

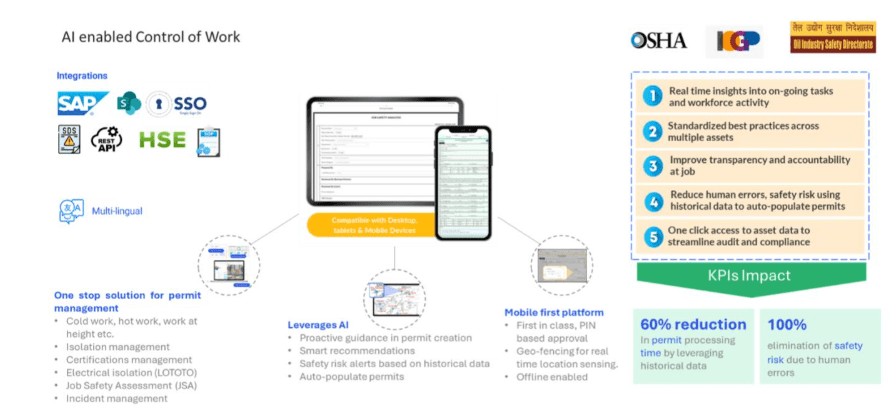

Maximl, founded in 2016, offers AI-powered industrial automation software that helps major oil refineries, optimize maintenance operations, reduce downtime, and be safer and more compliant with regulations and industry norms. Maximl’s software is live at some of the largest oil refineries in the world, including the largest (Reliance, Jamnagar).

In addition, we serve various process sectors: petrochemicals (such as Haldia Petrochemicals), metals (Hindustan Zinc), power generation (Vedanta Power), and upstream oil (Vedanta Cairn). These are some of the largest companies in their sector – globally.

We offer software in two areas – Shutdowns, Turnarounds, and Outages (STO) and Control-of-Work.

Control Of Work

In any manufacturing operation, there’s much maintenance work on an ongoing basis. In process industries such as downstream oil and petrochemicals, the possibility of hazard is high and therefore permit to work assumes special importance (i.e. relative to discrete manufacturing).In such industries, the workflow and rules governing raising a request for and the issuance of a maintenance job permit must have a high level of rigour built in.

This is where a Control-of-Work (CoW) solution comes in.

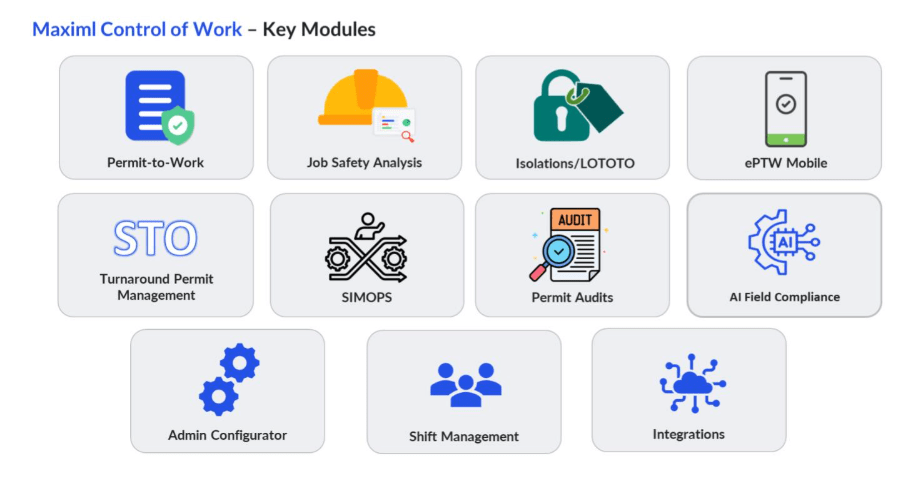

CoW is an established category that has a well-defined set of features.

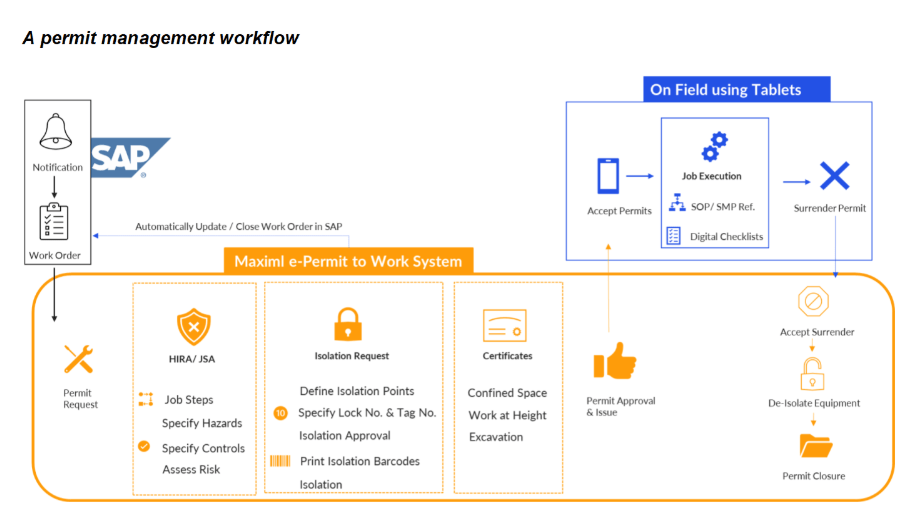

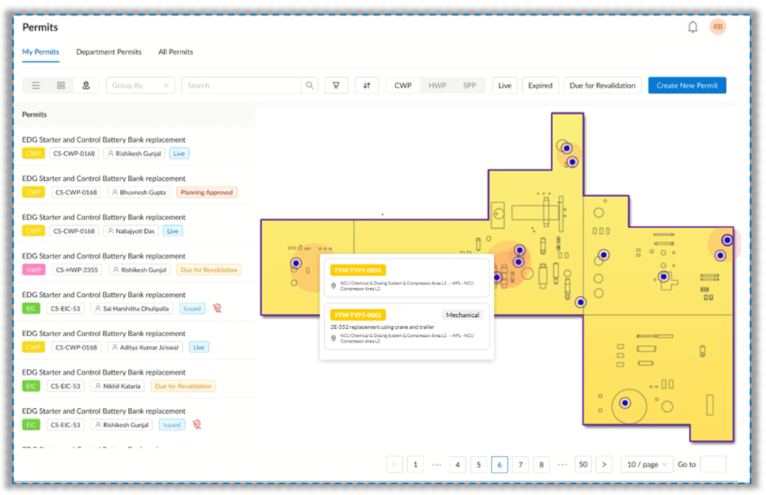

The CoW product enables the process of permit management wherein an employee or contractor can request for permission to perform a specific maintenance job at a site involving a particular equipment with the request thus made finding its way to the appropriate authorities and the permit being granted after the requisite paperwork has been filed.

CoW in industries with hazardous materials gets complicated quickly. For the maintenance activity to be safe, the site of work should be made safe by the appropriate controls, in terms of isolating the work area from energy/chemical flows and concurrent work, in accordance with regulations, industry norms, and the standard operating procedure that are company and plant specific. All concerned authorities, those in charge of systems that determine the exact situation at the work site – all man, material and energy flows, must sign-off said work. The authority specifically in charge of the work area must sign it off too. These set of features is called Permit to Work (PTW)

A permit to work document comes attached with all certificates necessary. Each certificate attests to the permit bearer checking off one prerequisite for the work to happen.

The workflow is in the context of plant assets

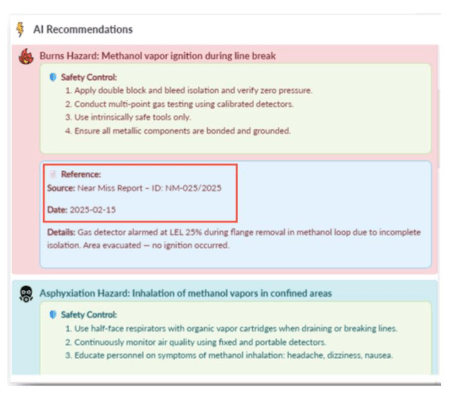

There is an abundance of minutiae involved. Will the work involve excavation? Is an industrial gases plant that produces and stores liquid oxygen situated near a job that involves ignition? Such a job can only happen at a site that is physically distant from any zone where the air might be oxygen rich.

What is the weather likely to be on that particular day? If the wind speed is high, working at a significant height might not be a good idea.

Therefore, a permit-to-work must incorporate information about what goes with what, and what’s in conflict with what, across a bewildering range of possibilities in terms of jobs, flows, material, equipment, sensors, tools, vehicles, hazards, and regulations in a three-dimensional space, situated in a jurisdiction. and resting on decades of history.

Permit-to-work lies outside the purview of ERP

The toolset to support this complex interplay of man and machine is surprisingly inadequate. The ERP holds the state of plant assets at the time of commissioning, design, or at the time of the ERP go-live. The enterprise software ecosystem – the data model, the UX, the features, the workflow – were all designed for the corporate knowledge worker, not the deskless industrial field worker. It’s the site of record keeping, not the site of work. The de facto state of the plant is often locked in paper, P&ID and GA diagrams, inspection reports in PDF form, the minds of plant veterans, and even stacks of paper.

Very little of it ends up in the ERP. When it does, it’s dated on arrival, at a level of aggregation that serves no functional purpose for the plant personnel who must keep production running on an ongoing basis.

Therefore, much of the day-to-day aspects of asset maintenance at a plant happens over informal channels such as group chat and is driven by the implicit knowledge of a few, highly tenured and dedicated employees (as is the case with shutdowns and turnarounds). The trouble is that many of these tenured, dedicated employees will soon leave the workforce.

For software to be an enabler of work for the plant worker (and not merely a system of record keeping for those at the headquarters) the benefits said software offers to the worker must surpass the status quo (paper, group chat, and gut feel) by 10X.

This applies both to large-scale maintenance projects and routine maintenance, and therefore to both our offerings – STO and PTW