What Maximl does

Maximl, founded in 2016, offers AI-powered industrial automation software that helps major oil refineries, optimize maintenance operations, reduce downtime, and be safer and more compliant with regulations and industry norms. Maximl’s software is live at some of the largest oil refineries in the world, including the largest (Reliance, Jamnagar).

In addition, we serve various process sectors: petrochemicals (such as Haldia Petrochemicals), metals (Hindustan Zinc), power generation (Vedanta Power), and upstream oil (Vedanta Cairn). These are some of the largest companies in their sector – globally.

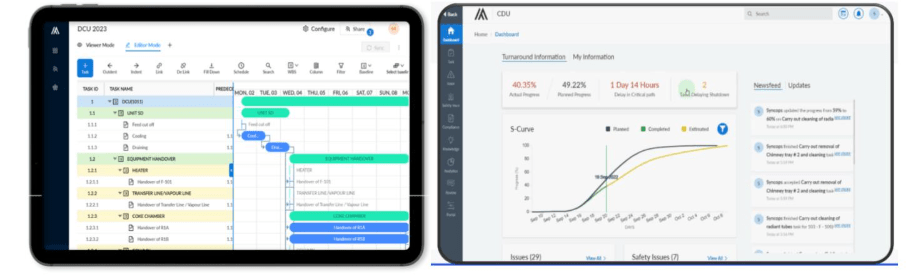

We offer software in two areas – Shutdowns, Turnarounds, and Outages (STO) and Control-of-Work.

Shutdowns, Turnarounds, and Outages

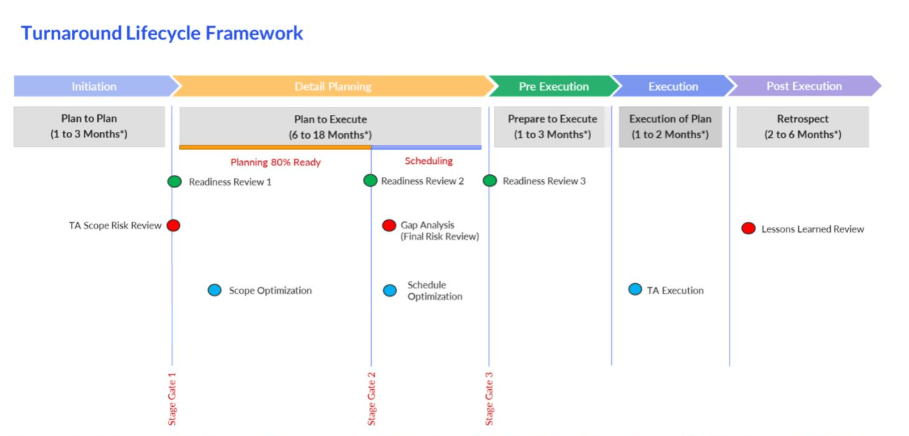

In manufacturing, particularly, in process manufacturing, the production machinery (that takes in feedstock from one end of the plant, such as crude oil, and yields the output – such as gasoline, kerosene, and aviation fuel – at the other) must be taken offline periodically. Such turnarounds can be due to a need for maintaining, renovating, or refitting facilities. The facilities of the machinery are thoroughly inspected during shutdowns and turnarounds. This typically happens every 3 to 5 years. Other process sectors have different periodicities, and the process is known by different names (such as “shutdown” in Oil and Gas, ‘overhaul’ in power). But planned downtime is standard.

This turnaround lasts anywhere from 3-5 weeks. These planned maintenance projects are high stakes. Every additional day the assets stay offline costs the company millions in lost production and therefore sales. Higher the downtime, greater the loss. Turnarounds need to be planned well, with downtime being a major planning consideration. Any deviance from the plan increases downtime (and therefore lost production), maintenance spending (external, and multiples of routine maintenance) and negatively impacts both the topline and the bottom-line.

During a shutdown, equipment is inspected for corrosion, deposit formation, general wear and tear, miscellaneous repair of parts (including rotating parts), and the outright replacement of parts This is typically a difficult time for the plant. The bulk of the work is done by external contractors. The volume of maintenance activity shoots up by a factor of 10 relative to routine operations.

One would expect projects of such scale to involve in-depth planning and measures to ensure deviance from the plan is controlled.

In addition, we serve various process sectors: petrochemicals (such as Haldia Petrochemicals), metals (Hindustan Zinc), power generation (Vedanta Power), and upstream oil (Vedanta Cairn). These are some of the largest companies in their sector – globally.

We offer software in two areas – Shutdowns, Turnarounds, and Outages (STO) and Control-of-Work.

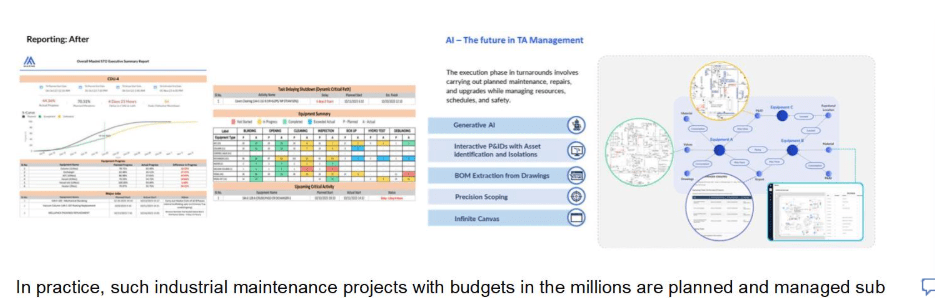

In practice, such industrial maintenance projects with budgets in the millions are planned and managed sub optimally, with tools and artifacts that are not built for purpose and archaic- with static planning documents, group chat, focusing less on planning, and more on managing the execution phase, relying on the implicit knowledge held in the minds of a small group of plant veterans, and short-term trade-offs.

This scenario is characterised by low levels of planning maturity and is plagued by five concerns:

- The manufacturing workforce is ageing. As the current generation of shutdown/turnaround experts retire, a crisis of competence looms. Talent is scarce. How does one replicate the best planner who holds much of the knowledge in an implicit and unstructured form? In the absence of formal knowledge systems, there’s a disturbing pattern of reliance on a few experienced employees.

- In practice there’s a gap between the plan as designed by the central command, and execution of the plan as it happens on the ground. Much leadership bandwidth is wasted on carrying information back and forth. The information transfer latency contributes to deviation from the plan, in terms of cost, schedule, and quality.

- A level of uncertainty is innate to the business of large-scale planned maintenance. Requirements sometimes surface only when the equipment is examined – in detail, on site, from inside the heavy-duty machinery. The industry calls this ‘emergent work’. Without a strong layer of factual information rooted in the history of the plant, volume of emergent work is hard to predict.

- The ERP is rarely current and updated. Mostly, the ERP backbone undergirding plant operations operates on a data model relevant only to central management. The state of plant assets (equipment, sensors et al) is typically entered into the ERP system when an assessment is conducted by an external consultant. But the volume of information is such that not all of it (such as the spatial, logical, physical interrelationships between assets) finds its way into ERP, and since ongoing work introduces changes to the status, the information in ERP is rarely current. Instead, the state of equipment is locked into P&ID diagrams GA diagrams in PDF, JPEG, or paper form. To summarise, the situation is one of dated, imperfect information – that naturally introduces deviation from the plan, and hurts quality

- The most used project and portfolio management tool was built not for process engineering but for the EPC industry. In addition, the tool (s) in question operate at a level of abstraction that’s too high for actual planning and scheduling. The PPM tool remains limited to a small group of planners and has little bearing on the project as it unfolds. Therefore, in practice, it is used more for reporting the plan to a higher authority as opposed to building a working, dynamic plan and schedule for those commanding the actual turnaround work. Because of the inadequacies of tooling, the system drifts towards deprioritising commitment to a formal plan and managing the project and the inevitable surprises that arise with ad hoc measures, diktats – all in a state of expensive confusion.

So, how does one solve this?

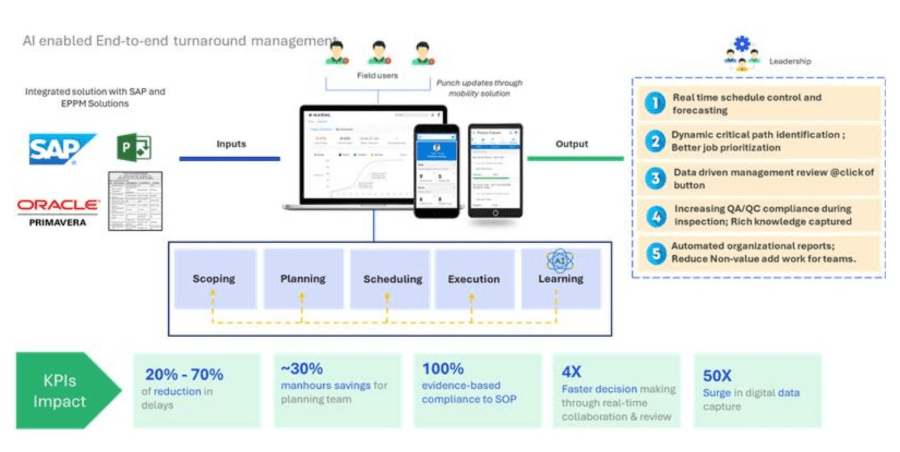

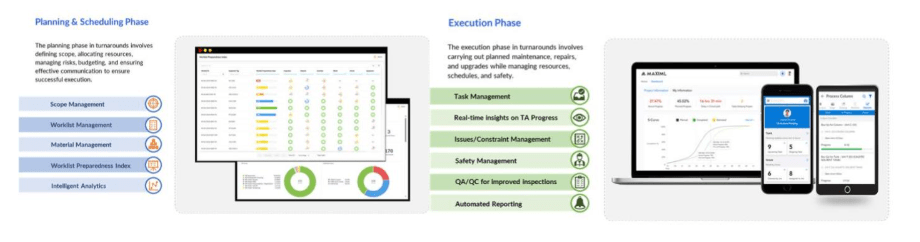

The Maximl approach to solving such problems makes use of five levers:

- AI to ease data entry, democratize expertise, and learn from past work. Maximl has judiciouslyused AI agents wherever a wealth of best practices exists, such as to automate job packages information. In addition, Our AI/ML tools that can use previous plans and other existing client-specific literature (such as Turnaround postmortem reports and inspection reports) to automate much of the heavy lifting plan development, These AI capabilities were built to address management concerns that can summed up as ‘what happens to my plant after these five guys are gone?”

- Our mobile software allows deskless field workers to report status from the actual job site, reducing information transfer latency from the field to the office, bringing down what used to take days and hours to now in minutes. This allows plant management to focus on what matters, as opposed to carrying information back and forth. Deviations from the Turnaround plan are expensive and mobile communication allows real-time monitoring of progress.

- Our computer vision and natural language processing algorithms extract usable information from P&ID and GA diagrams, helping populate the asset hierarchy. In practice, the ERP backbone doesn’t hold the latest in asset interrelationships. AI addresses this by getting to the de facto source of updated information and churning out tabular data that can then be used by other applications for more efficient and safer operations.

- A large-scale periodic maintenance project such as a turnaround is in practice made of many small, tightly defined maintenance tasks. Each individual task must be executed safely and efficiently by authorised personnel with the correct approvals from every stakeholder, with watertight processes for ensuring the work site has been cordoned off from a chemical, mechanical, and electrical standpoint. In addition, every site and job must check off boxes such as whether an activity will be performed at a height – which kicks in appropriate enablers (such as scaffolding) and safeguard. In addition, personnel must also be aware of all relevant hazards. This brings us to our second major product.