According to Gartner, 91% of businesses are engaged in some form of digital initiative. These businesses, depending on the scale of their initiative, gather data that can be used to measure several performance metrics and gain insight into its operational process. From this insight, the business can adjust its processes for greater efficiency, productivity, and revenue. In this article, we look into 3 key metrics that manufacturers can measure and how a connected worker platform can enhance the performance of each metric.

What’s measured improves – Peter Drucker

Metrics are important for several reasons. They tell us more about processes, people, and entities. It’s no different in the manufacturing industry where performance metrics can serve as ‘quantifiers’ for a factory’s workflow and processes.

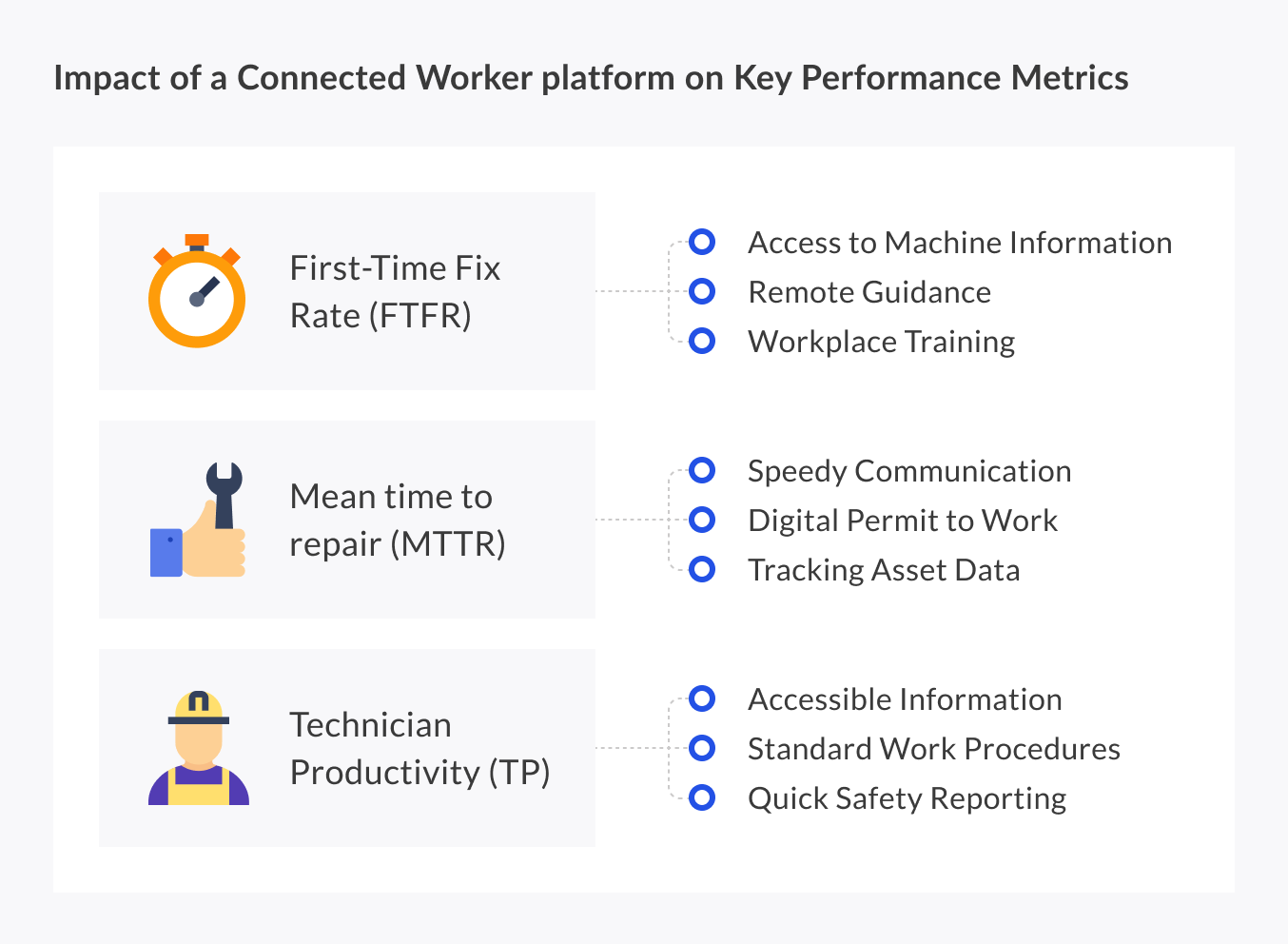

Here are 3 key performance metrics – First-Time Fix Rate (FTFR), Mean time to repair (MTTR), and Technician Productivity (TP) – and how they fare with and without a Connected Worker platform

1. First-Time Fix Rate (FTFR)

The First-Rime Fix Rate is a metric that denotes the proportion of problems tackled at the first attempt.

How a Connected Worker platform enhances FTFR

Access to machine information

Without: The likelihood of a botched fix increases if a technician doesn’t have access to important machine information i.e., machine specifications, operating condition over time, and comments from previous technicians. With the flurry of activities on most factory floors, this information may not be available on time, or unavailable because of improper storage.

With: A Connected Worker platform allows factories to digitize machine data and make it easily accessible for technicians. As a result, technicians will not have to resort to ‘blind’ fixes and can carry out more efficient fixes the first time. And unlike frail paper storage, cloud storage – as used on the platform – will ensure the information lasts longer.

Guidance for Technicians

Without: Nowadays, factories are populated by increasingly sophisticated equipment, some of which may require specialized repair skills – limited to a few. Chances are, your {present} technician will not have the specific know-how for a machine and logistics may limit the factory’s ability to bring in an external technician. In this situation, the only obvious options are to trust the available technician and hope for the best or wait till an expert can be brought in.

With: Through a Connected Worker platform, a knowledgeable company technician or an external expert can remotely collaborate with on-site personnel using live audio and video feeds. This will save time, eliminate assumptions and increase the odds of success at the first attempt.

Workplace training

Without: Repetitive processes or boring paper manuals do not sufficiently equip workers with the robust skills needed to fix modern machines.

With: A Connected Worker platform enriches the quality of workplace training with top-of-the-line training tools that will sharpen the skill-set of technicians. Technicians may have digital repair workshops where they brainstorm with experts, view rich ‘mechanical’ videos, or practice virtual ‘fixes’. Moreover, prior to a fix, they can use digital-walkthroughs to mentally prepare for the procedure and pre-empt bottlenecks that may arise.

2. Mean-Time to Repair

Mean-Time to Repair is the average time difference from when a repair work order is initiated by the technician to when the work order is closed. It is the average time it takes to repair equipment and restore it to its optimum operating condition.

How a Connected Worker platform enhances MTTR

Communication

Without: Ineffective communication – horizontally and vertically – will breed confusion on the factory floor and leave everyone on a different wavelength. Consequently, reports of a faulty machine may not get to the line managers on time, and technicians who were ‘notified’ of a repair procedure may not receive notifications at all.

With: A Connected Worker platform increases the speed, effectiveness, and reach of communications. Faulty machines can be quickly reported and tasks can be assigned to the appropriate technician without delay. With mobile alerts set-in, technicians will receive notifications in real-time and enact faster repairs.

Approval of permit to work

Without: It’s not unusual for those with the say-so to be in different locations from field workers. They may be working at the office or tending to affairs at another of the organization’s facilities. Waiting for managers to show up for the approval of work permits may shift the repair schedule by hours, days, or even weeks.

With: Using a Connected Worker platform benefits both repair technicians and managers. Technicians can build standard permits within minutes and send them to managers on the platform. Managers can then run through these permits from the comfort of their mobile devices, and indicate approvals or rejections.

Asset condition and inventory

Without: The manual process of monitoring inventory is susceptible to errors. Poor inventory management may lead to a situation where technicians have to wait for inventories to arrive, which could take a significant chunk of time, depending on the quality of the supply chain. And because managers do not have visibility into asset condition, they cannot take proactive actions to stock up on inventory, in preparation for machine failure.

With: Digitizing machine data and inventory provides a greater asset and material visibility. For plant managers, they will have a dashboard to view real-time machine data (obtained from sensors) for asset monitoring. Also, machine data will indicate when asset maintenance is due and the data patterns will help managers project machine failure and prepare spare-parts on time.

3. Technician Productivity

This is a metric designed to maximize worker utilization, it is the percentage of productive hours a worker expends over a period of time compared to the total working hours during that period.

How a connected worker platform enhances technician productivity

‘Waiting’ Time

Without: There are a lot of productivity ‘slayers’ in a manufacturing operation. They may include the time spent: combing through large paper materials, hanging around for permit approvals to come through, and stopping for changeovers. Not only do these hamper productivity during the period in view, but they can also do so in the near future as it may take some time for technicians to mentally readjust and get back into the swing of things.

With: A Connected Worker platform can function as a digital library for all the factory’s reference books, relevant documents, and procedural information. The keyword function and rich search tools at their disposal will allow technicians to find information in seconds without impacting their productivity. Also, on the platform, approval of permits is a breeze and digital check-ins (with timestamps) can be introduced to create more accountability during changeovers.

Work processes

Without: It is difficult to achieve workplace synergy and improve productivity when technicians are oblivious of their roles at every point in time. Many factories that function manually are disorganized – with limited productivity – because instructions are not clear, timely, and personalized.

With: A Connected Worker platform streamlines work processes for greater productivity. On their dashboard, technicians can get notifications, view work instructions in real-time, and pose questions to stakeholders. Managers, on the other hand, can shift personnel and project-manage in an all-inclusive yet personalized manner.

Safety standards

Without: Quickly circulating safety standards and procedural updates across the shop floor is very important to keep up the productivity levels. When these standards are not shared effectively, an accident is more likely to occur that may result in downtime and negatively affect productivity.

With: Using the share feature on a Connected Worker platform, managers can rapidly get across safety updates on the shop floor without fuss. Technicians will receive notifications of such updates and can quickly implement them in their work procedures. The outcome will be a safer and more productive workplace.

Maximl’s Connected Worker Platform enables real-time communication, knowledge-sharing, and seamless collaboration. Cloud-based, it integrates information across systems and centralizes this information for enhanced insight – providing a single version of truth to stakeholders.